This clever adjustable support cradle provides a perfect solution where flooring or decking requires a minimal elevation height. Simple to install and adjust. The cradle can accept any joist up to a maximum width of 48mm (2'' nominal). This product is a very popular and cost effective solution for the installation and leveling of roof-top decking and internal flooring.

Made of PP (polypropylene).

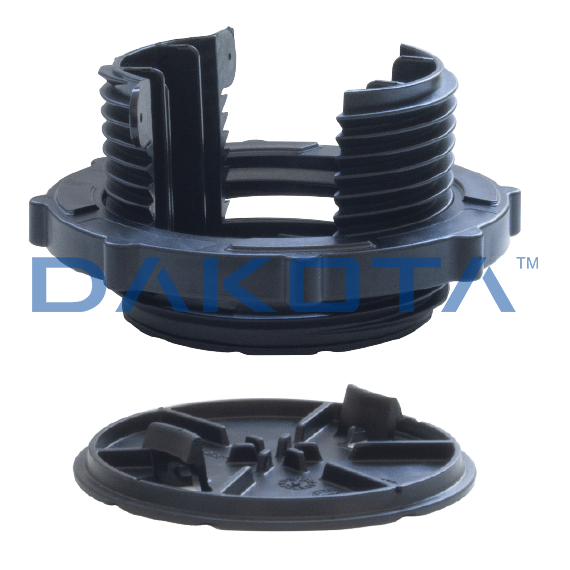

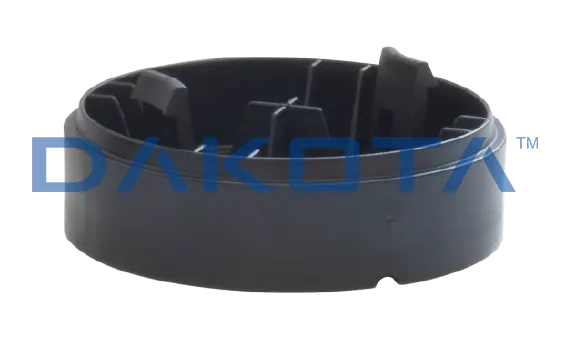

The support cradle comprises a threaded support with adjustment ring and a clip-in rubber base pad. A 20mm (¾") extender, which simply clips into the main support base in place of the rubber base pad, is available to increase the height range of the system. These can be used in multiples.

The support cradle is rated for an average maximum load of 365 lbf (166 Kgf). Using a recommended minimum of 6 to 8 supports per square yard, this is equivalent to 243 to 324 lbs/ft².

| Code | Product | Size mm (in.) WxDxL | Pk | Pallet Qty. | UM |

|---|---|---|---|---|---|

| TER09-1164 | Adjustable joist support with rubber pad | 14mm to 50mm (½'' to 2') | 30 pcs. | 2,700 pcs. | 1 pc. |

| TER09-1164/P20 | Clip-in Height Extender | h. 20mm (h. ¾'') | 60 pcs. | 6,480 pcs. | 1 pc. |

Use positioned on any firm surface as a base for the laying of joists during the installation of the under structure for floors or decking. For internal wood flooring it removes the need for leveling screeds and can be installed directly onto damp-proof membranes.

We suggest a minimum distribution of 6 to 8 supports per square yard, with joists spaced at 16" centres and supports positioned at 16" to 20" intervals along each joist. Where high loads are anticipated the weight bearing capacity can be increased by placing the supports closer together. When installing heavy, pre-built, joist frameworks, take care not to overload any single point of support during initial positioning and leveling. This can be avoided by using support wedges or jacks to reduce the weight until the required distribution of the supports is in place and adjusted.